“As an Amazon Associate, I earn from qualifying purchases. Without Any Extra Cost to You!”

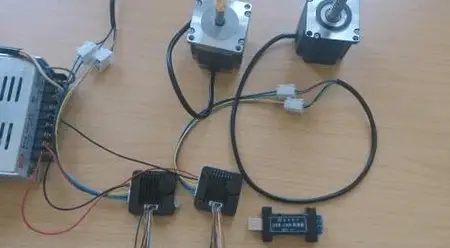

A stepper motor is also referred to as a step motor or a stepping motor. It is usually a brushless electric motor supplying direct current.

Many customers aim to utilize motors in conjunction with a battery power supply. This power supply ranges from basic designs to complex portable devices.

This article will look at some of the most often asked questions we receive from battery users. Besides, it also chalks out some potential dangers that need consideration.

Things to consider before powering the stepper motor with a battery

1. How long the battery will last

- We must first determine the battery’s capacity.

- Next, we have to find out the amount of current the motor will draw. We measure the capacity of batteries in milliamp hours or mAh. This indicates how many hours your battery can supply one milliampere of current.

2. The voltage of your battery

- All cells are not equal. So make sure the voltage is set to a suitable level before using them. For example, a 3V motor will most likely run on a 1.5V AA battery. On the other hand, utilizing a 3V battery with a 1.5V motor rated at 1.5V causes the motor to burn out sooner than expected.

- Motors turn more slowly as a result of the lower voltage. DC and gear motors’ torque handling capabilities reduces. Hence, the vibration reduces. Aside from that, specific battery designs have different voltages. For example, AA batteries. The most popular rechargeable batteries have a voltage of 1.2V. That makes them the worst offenders.

- Steppers run on 5-12V, although most tiny battery stacks provide 1.5-5V. They require fewer turns of thicker, lower-resistance wire to work at lower voltages. Fortunately, most manufacturers fulfill special requests for a nominal fee. Or even for free.

To purchase a custom-wound motor, you must specify the coil current (ICOIL). This coil is the RMS motor current.

Pick a motor that can generate the required torque at 50-70 percent of its maximum current rate. This helps reduce resistive losses and allows some headroom.

It is necessary to calculate the current required to generate the torques. You can calculate it using the manufacturer’s original motor specs.

3. The battery capacity

To determine the value of mAh, you need to meet highly particular test parameters. This is not possible typically. The battery may operate in real-world applications.

But it will deplete quicker when the current drawn is more significant. For instance, a battery with a 1600 mAh value will provide one mA for approximately 1600 hours. However, this will not provide 1.6A for an entire hour.

You might also consider connecting two batteries in a series. While maintaining the same voltage and increasing the capacity.

A typical laptop battery has four cells in series to boost the voltage. And two parallel sets of four series cells for higher capacitance.

4. Voltage shift of your battery

The voltage of batteries decreases as they discharge. When using specific types of batteries, this effect will be more obvious. However, it can fail if the application gets closer to the limits of the battery’s capacity.

There is a difference between Typical Start Voltage and Certified Start Voltage. The stall torque of direct current and gear motors will decrease.

If it worries you, use a battery with a higher voltage than you require. Turn on a voltage regulator for the constant voltage you want.

5. The stay current

Motors consume more current when they are first turned on. Rather than their regular operation. This results in shorter battery life than during normal operation.

Frequently Asked Questions

What is the outcome once a DC motor uses a 3v battery?

Using a 1.5V motor with a 3V battery might cause rapid harm. Motors spin slower due to lower voltage. This limits the torque handling capacity of DC and gear motors. While increasing the vibration motor’s vibratory frequency.

Which is the best voltage to start on a motor?

Understand the differences between the Typical Start Voltage and the Certified Start Voltage. The stall torque of direct current and gear motors will decrease.

Conclusion

Stepper motors have segmented rotor and armature architectures. They allow them to rotate in short, precise, and distinct steps. Moreover, they hold their position even when not driven.

As a result, they perform effectively on positioning surveillance cameras and remote sensors.

Additionally, they help in activating air vents, valves, and window coverings, among others. When purchasing these motors, always go for the best quality.

As a general rule, you should never deliver the entire supply current to the motor coils. Instead, you should utilize a current feedback mechanism.

This mechanism will drive the coil with enough voltage. That causes the coil to draw the predetermined driving current.